2022-08-11

EMI Shielding Materials are used to prevent electromagnetic interference (EMI) from entering or leaving an electronic product, thereby maintaining the electromagnetic integrity of the device. They are also known as Faraday cages or Faraday shields. Dielectric and conductive materials such as Ceramic, Plastic, Aluminum, and Conductive Powders are employed for EMI Shielding. They are instrumental when designing products that contain sensitive electronics such as computers or medical devices.

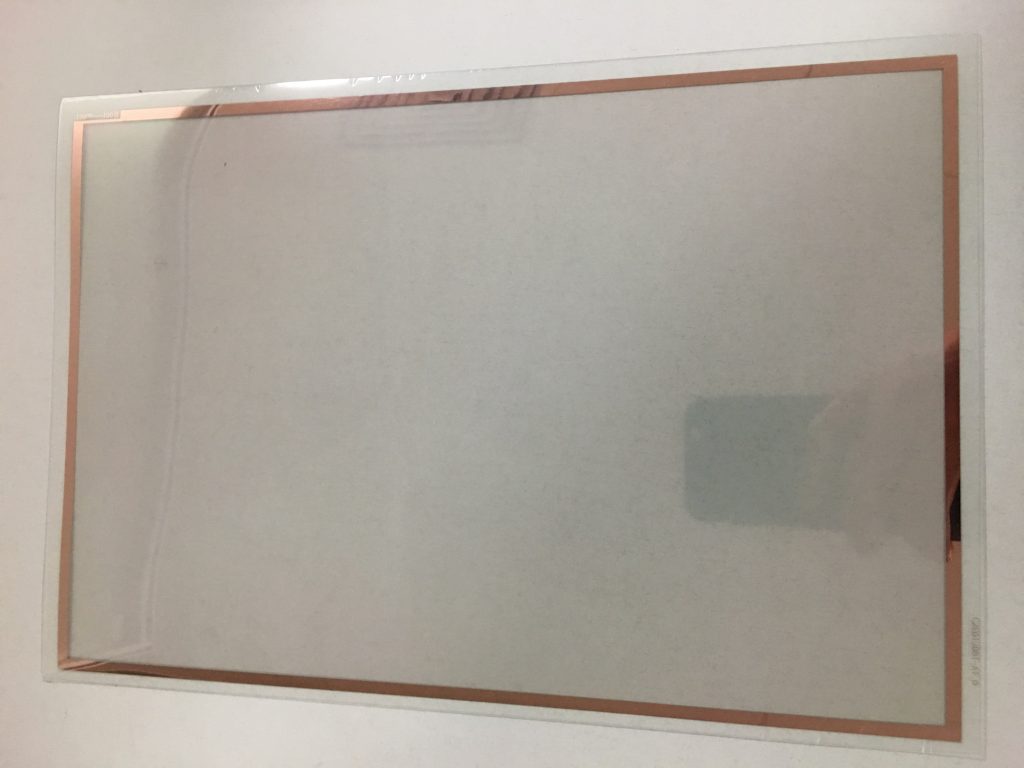

Electromagnetic interference is known as EMI. It is a frequent issue that may result in everything from static on your Television to a complete loss of power. By obstructing or reflecting electromagnetic waves, EMI shielding materials can aid in preventing these disturbances. Metal foils, metal meshes, and conductive polymers are the most typical materials. Metal foils are excellent in reflecting electromagnetic fields and are often constructed of copper or aluminium, and they are also exceedingly brittle. Metal meshes are significantly more durable. The most effective shielding material currently available, conductive polymers provide the perfect performance.

The two main categories of EMI are as follows in given below:

Broadband disturbances are frequently generated by items like electrical power lines, but narrowband disorders are generally caused by gadgets like radios, Television channels, and mobile phones.

A narrowband electromagnetic disturbance has a bandwidth that is less than or equal to that of specific measuring equipment, receiver, or vulnerable device. Accordingly, an electromagnetic disturbance with a bandwidth higher than a particular measuring instrument, receiver, or susceptible device is called a broadband disturbance.

Shielding materials work by either absorbing the electrical signals that are generated or by reflecting them into space. These materials convert the EMR into heat and immerse the converted energy. A floor connection or a virtual ground plane absorbs the current created when a signal enters your device or is emitted from it due to the EMI shield’s absorption of the movement. For instance, modern smartphones require a variety of complex electronics to operate simultaneously for the device to function. EMI shielding keeps these complex components from reacting negatively to random signals and waves that may damage the phone. It is now an essential component in smartphones and other electronic devices.

The most common type of material used in electronics production is an aluminium coating called EMI shielding or electrostatic discharge (ESD) material. The benefits are given below:

These materials must be tested against different electromagnetic radiation levels to improve their performance. To test the effectiveness of these materials, they are exposed to an electrical field and subjected to varying frequencies of EMIs. The results of these tests help manufacturers design better EMI shielding materials. They have been used in various industries such as electronics, aerospace, automotive, medical devices, etc. They are also used in consumer products like mobile phones, etc.

These shielding materials protect electronic equipment from electromagnetic interference (EMI). They are also used to prevent radio frequency radiation from damaging sensitive components. To ensure the proper functioning of electronic devices, they must be shielded against EMI. They also protect other types of radiation, including X-rays, gamma rays, and cosmic radiation. They also help control electromagnetic noise so that sensitive electronics do not become overloaded or damaged by it.

These shielding materials offer better performance against electromagnetic interference (EMI) than traditional metal shields. They provide superior protection from EMI noise by absorbing or reflecting the energy instead of allowing it to pass through. These materials will enable the passage of lower frequency signals instead of traditional metal shields, which block high-frequency signals. The effectiveness of a shielding material depends on its thickness, conductivity, weight, density, and permeability.

How do you select suitable EMI shielding materials?

There are many things to consider when selecting suitable shielding materials. Some essential points are as follows in the given below:

Consider the specification and conductivity:

When selecting a shielding material, you should consider the following: weight, conductivity, ease of handling, etc. One needs to carefully analyze the specifications before buying the product.

The size of the product matters. You should choose one that fits the space where you plan to install the device.

Good shielding material should be affordable.

EMI shield has been used extensively in various industries such as electronics, aerospace, automotive, and many others. However, the environmental impact of these products needs to be considered when selecting them. Many factors must be taken into account before choosing a shielding material. You may have to also look at the environment when selecting suitable shielding materials.

When choosing shielding materials, you should consider the environment and the applications. The correct shielding materials should be selected based on the type of signal and the amount of shielding needed. When selecting shielding materials, factors such as performance, and environmental impact must also be considered.

An important factor when choosing a shielding material is its permeability and conductivity. Permeability refers to the ability of the material to allow the passage of electrons. Conductivity refers to the ease of movement of electrons within the material.

A proper selection of shielding material will ensure your device does not malfunction due to interference. To calculate the required size of an EMI shield, it is essential to consider its frequency range.

Shielding materials reduce the effects of EMI:

Sensitive components are less affected by EMI thanks to the usage of these shielding materials. Electromagnetic interference (EMI) is an unwanted electrical disturbance that occurs when electronic equipment emits radio waves or other non-electrical energy. It is a widespread problem in modern society, especially in mobile phones, computers, and many types of electronic devices. Most of our smartphones have built-in EMI protection systems, but they do not always work correctly. We may need to replace them, so learning about the best ones to buy can be significant. The best one EMI shielding materials that can protect against radio frequency signals from interfering with your smartphone’s internal circuits. You can also use these materials to shield your phone from external sources of RF radiation. It helps protect sensitive electrical devices from damage due to EMI radiation. A good EMI shield must provide proper protection against the harmful effects of EMI so that the device works properly. As the importance of EMI shielding increases, these products have been developed over time.

MICRON has been manufacturing shielding materials for many years. Our products are used in many industries, including aerospace, automotive, medical, telecommunications, and more. We have developed materials to improve the performance of the EMI shield. They offer higher levels of protection and enhanced mechanical properties. We are a leading manufacturer of EMI shielding materials used in many industries. This shielding material is used to protect electronic devices from electromagnetic interference (EMI) caused by radio frequency signals. We have developed an innovative material that offers superior performance compared to conventional materials. We also provide custom solutions to meet the specific demands of our customers. To learn more about our products and services, contact us today. We look forward to serving you!